UTG COMPANY

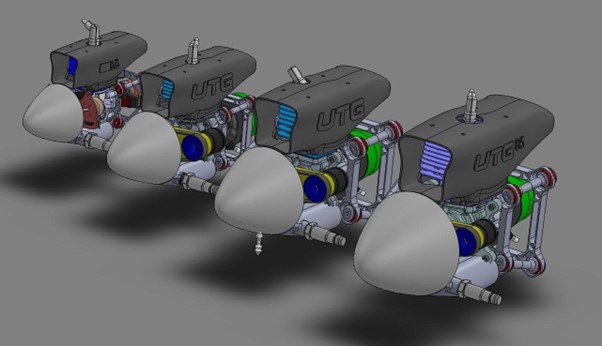

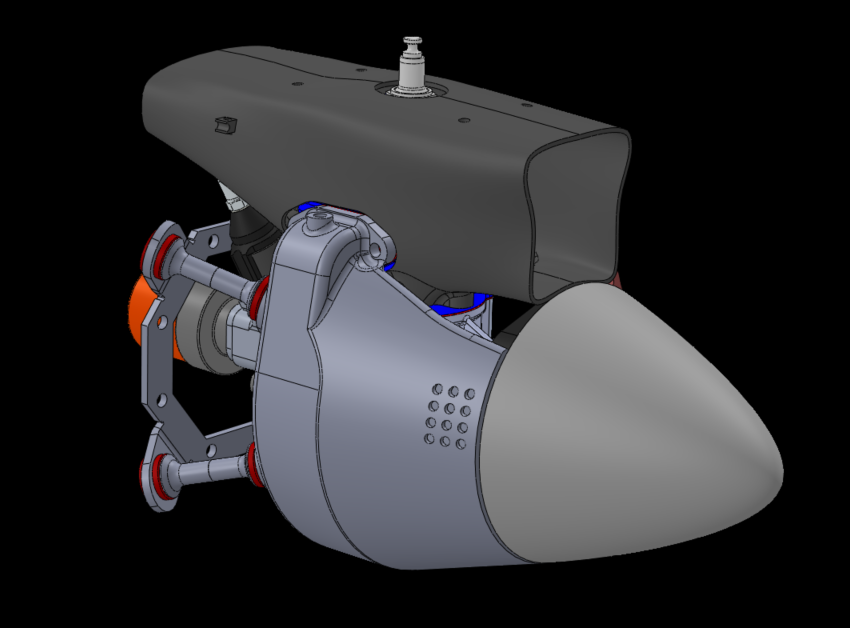

UTG is a global leader in propulsion systems and fuel injection technology for unmanned aerial vehicles (UAVs), catering to both military and commercial applications. Our engine offerings include powertrains for UAVs, UAS, and drones, designed to meet all the specific needs of these applications. Our comprehensive solutions feature a fuel injection system, a silent exhaust, a generator, and an anti-vibration system to prevent engine vibrations from reaching the flight controller and payload. Our range spans from the compact UTG10, with just 10cc for the smallest UAVs, to the robust UTG85, with 85cc for heavier unmanned aerial vehicle applications. UTG provides a variety of standard engines including 20cc, 30cc, 55cc, and 85cc, along with custom versions of 10cc and 15cc. This allows us to accommodate a wide range of UAV sizes and weights. In addition to our engine products, UTG offers engineering and development services, as well as design engineering consulting for both local and international clients. If you do not find the engine you are looking for among our products, please do not hesitate to contact us. UTG upholds a quality assurance system that has been successfully audited by Tier 1 military clients. Our quality system includes:

Robust Design and Testing Procedures for New Products

At UTG, we adhere to robust design and testing procedures for all new products. For instance, our UTG20 engine has successfully completed the rigorous 150-hour endurance test as specified in Part 33 of the U.S. Federal Aviation Regulations (FAR 33).

Comprehensive Assembly Guides

We provide detailed assembly guides for each product to ensure consistency in the construction processes.

Thorough Testing

All engines and modules undergo 100% testing before shipping. Each main component comes with an acceptance sheet, and every product includes a Certificate of Conformity

Component Serialization System

We have a system for serializing components to facilitate part tracking.

Comprehensive Documentation

Our products come with user manuals, integration guides, and interface specifications. For example, the UTG20 engine includes an operation and service manual.

OUR ADVANTAGE

UTG stands out in the UAV industry with our groundbreaking technology and proven operational expertise, uniquely positioning us to meet high-performance requirements. Our world-class propulsion solutions excel in reliability, power, and system durability, surpassing industry benchmarks. Our advanced fuel injection system supports spark ignition with heavy fuel, essential for military applications due to specific fuel logistics, defense policies, and site security. We lead the market in providing real-time diagnostics for propulsion systems. With years of proven experience in engine design, we have developed an exceptional supply chain network, ensuring the highest precision components for our propulsion systems.

OUR CAPABILITIES

UTG is a global leader in spark ignition propulsion systems for fossil gasoline, petrol, alcohols, bio fuels, efuels and heavy fuels, designed for both commercial and tactical unmanned aerial vehicles (UAVs). We offer a comprehensive range of services, including development, testing, validation, production, and engine reconditioning. Our dedicated in-house team, with the right blend of academic qualifications and practical experience across mechanical, electrical, and production engineering fields, takes clients' requirements from concept and definition through to marketing and ongoing support services.

Comprehensive Design and Development Process

UTG employs a thorough and methodical approach to designing and developing engines, components, and systems in both mechanical and electrical/electronic domains.

- Structured Phases: From initial concept to mass production, the process is divided into distinct

- Advanced Analysis Tools:

Utilizes the latest in computer-aided modeling and engineering technologies.

- Design Iteration: Incorporates prototyping and detailed testing procedures, along with drafting, measurement, and analysis.

- Control System Development: Involves programming, coding, and rigorous testing of control

- Computer Tools and Applications: Leverages sophisticated software and applications throughout the process.

- Stringent Validation: Ensures quality and accuracy at every stage:

- Conceptualization

- Prototyping

- Design verification

- Production validation

This comprehensive process has been successfully applied to a wide range of applications.

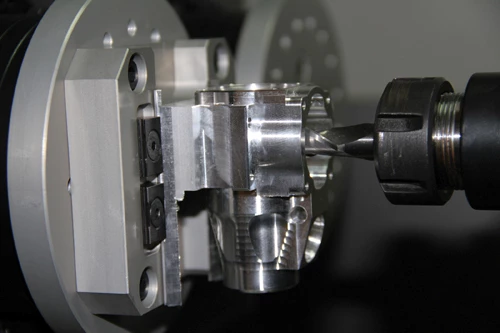

Machining and Prototype Creation

UTG’s in-house manufacturing capabilities include:

- Rapid In-House Production: Facilitates quick prototyping and production of engines and components, ensuring swift

project progression.

- Additive Manufacturing:

Employs advanced 3D printing technology to create detailed and intricate parts.

- Versatile Machining Equipment: Features manual, NC, and CNC mills, lathes, and drills, allowing for precise and varied machining

- Electrical and Electronic Prototyping: Focuses on developing and fabricating prototypes for electrical and electronic systems.

- Quality Control Metrology Lab: Ensures all incoming and machined parts meet stringent

quality standards through precise measurement and inspection.

- Global, Approved Supply Base: Maintains a worldwide network of quality-approved suppliers,

ensuring reliable and high-quality material sourcing.

These capabilities enable UTG to efficiently transform innovative concepts into high-quality, functional prototypes and products.

Seamless UAV Propulsion Integration

Leveraging its success with small tactical UAVs, UTG can effectively and smoothly provide propulsion systems for various UAV categories. The company’s technological expertise covers several essential areas:

- Fuel Injection Systems: Advanced systems for efficient fuel management.

- Electrical Power Systems: Robust solutions for power generation and

- Control Systems: Sophisticated strategies for engine and vehicle

- Auxiliary Components:

Supporting systems and components for enhanced performance.

- Software and Firmware:

Integrated software solutions for system management.

This comprehensive knowledge base allows UTG to adapt and integrate their cutting-edge technology into different engine types—piston, rotary, or hybrid—and across all sizes of engines and vehicles, ensuring versatile and high-performing propulsion solutions.

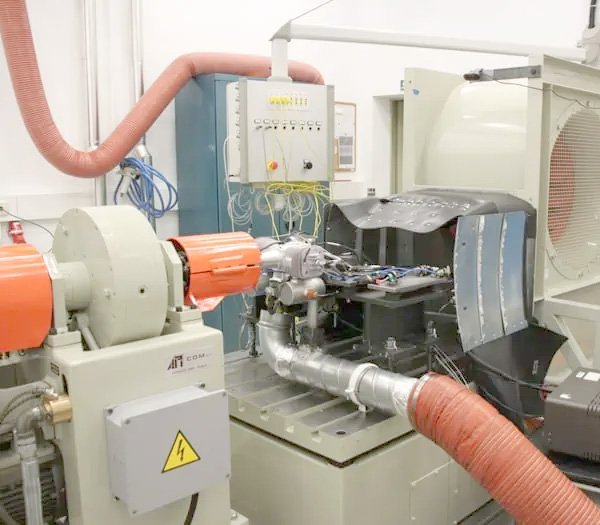

Testing UAV Propulsion Performance

UTG ensures the quality and reliability of its propulsion systems through meticulous testing and validation, drawing from automotive production

expertise and tailored to UAV requirements.

Scientific Optimization: Utilizes advanced analyses for stress, heat, airflow, balance, and vibration.

Validation Planning: Detailed plans based on Failure Mode and Effects

Analysis (FMEA) ensure performance in worst-case scenarios.

Comprehensive Facilities: Equipped with dynamometers, durability benches, environmental testing, NVH equipment, calibration setups, and stress detection tools, including altitude simulation up to 20,000 feet. Propeller durability benches are compliant with UAV engine FAR 33, paragraph 49 standards.

This rigorous approach guarantees UTG’s propulsion systems meet and exceed industry standards for reliability and performance in UAV applications

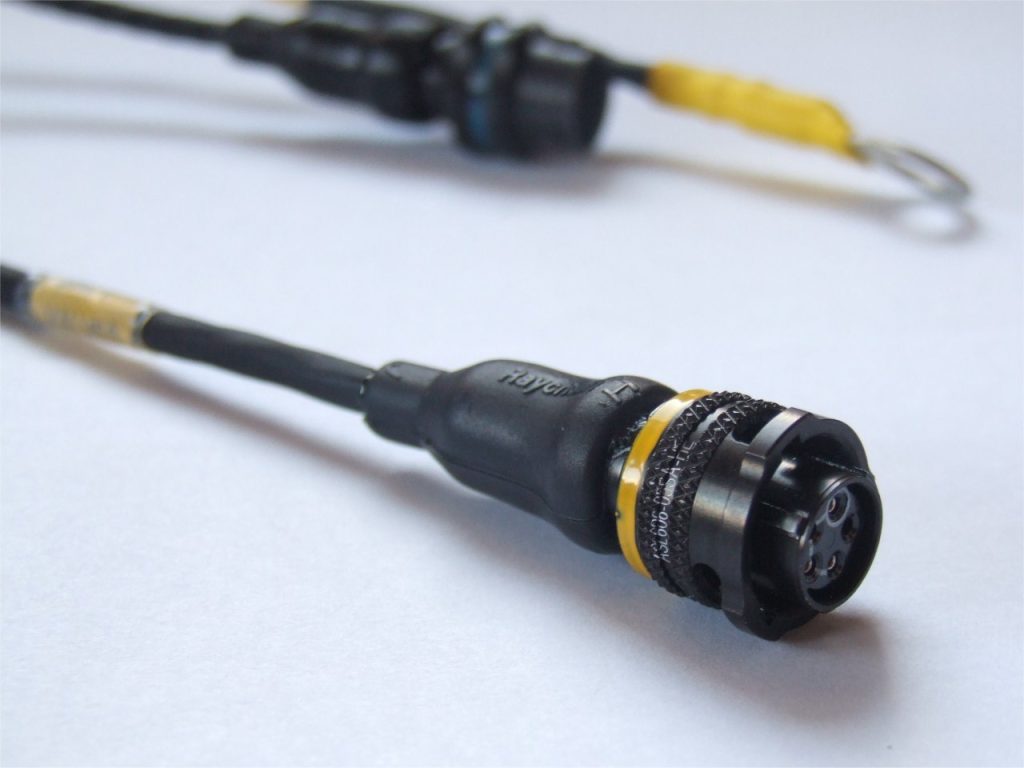

Fabrication & Assembly

UTG ensures top-tier quality and reliability in its propulsion systems, combining

- Precision Testing: UTG conducts meticulous testing and validation, meeting ISO 9001 standards for quality

- Comprehensive Evaluation: Advanced analytics optimize stress, heat, airflow, balance, and vibration, upheld by IPC-A-610 criteria for electronic assembly

quality.

- Thorough Planning: Validation plans, guided by Failure Mode and Effects Analysis (FMEA),

ensure robust performance under diverse conditions.

- State-of-the-Art Facilities:

Equipped with dynamometers, durability benches, environmental chambers, NVH tools, and stress detection equipment, UTG

adheres to IPC/WHMA-A-620 for cable assembly quality.

- ESD Control Commitment: Compliance with ANSI/ESD S20.20 safeguards against electrostatic discharge,

preserving component integrity. UTG guarantees propulsion systems of exceptional reliability and performance for UAV applications.

Testimonials

Our clients recount their experiences and results achieved with our services. Hear it from those who've experienced our commitment to excellence first-hand.

Works efficiently even in adverse environments...

"UTG has revolutionized our UAV operations with their exceptional propulsion systems. The seamless integration of components within a compact solution has surpassed our expectations, offering unparalleled reliability even in the most demanding environments.

From the silent exhaust to the precision of the injection and vibration systems, UTG's technology is truly impressive. Their ability to swiftly customize prototypes to meet our unique requirements has been instrumental in our success, demonstrating their commitment to providing tailored solutions.

UTG's expertise and guidance have been invaluable, allowing us to navigate complex challenges and stay ahead of the curve in the ever-evolving UAV industry. Their dedication to excellence and innovation has solidified UTG as a trusted partner in our mission to push the boundaries of UAV capabilities."

Alexander Hughes

SkyTech Innovations, USA

We chose to equip our FX-25 VTOL with the UTG20 engine…

“Equipping our FX-25 VTOL with UTG's UTG20 engine has proven instrumental to our project's success. This EFI single-cylinder 2-stroke engine boasts low fuel consumption and reduced weight, optimizing our aircraft's performance.

From integration to testing, our experience with the UTG20 has been highly positive. Its reliability during extensive testing and the exceptional support from UTG's team have been remarkable.

The UTG20 has undergone rigorous FAR33 endurance testing, exceeding 300 hours without critical issues, accelerating the military certification process for the FX-25 with the Ministry of Defense.

Overall, the UTG20's performance, minimal maintenance requirements, and support have exceeded our expectations, cementing its role as a reliable engine choice for our VTOL aircraft.”

Olivia Chen

StratAero Defense Solutions, Singapur