News

Enhancing UAV Performance with 3D Printed Exhaust Systems

Introduction:

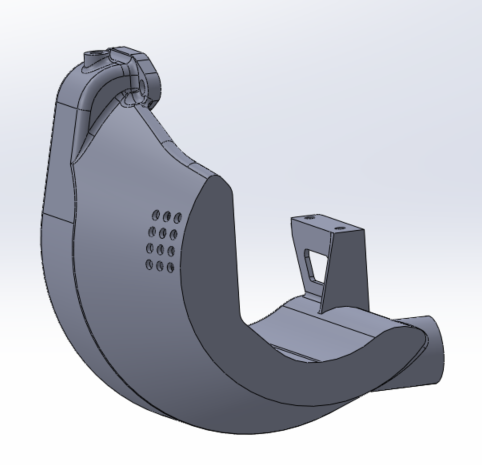

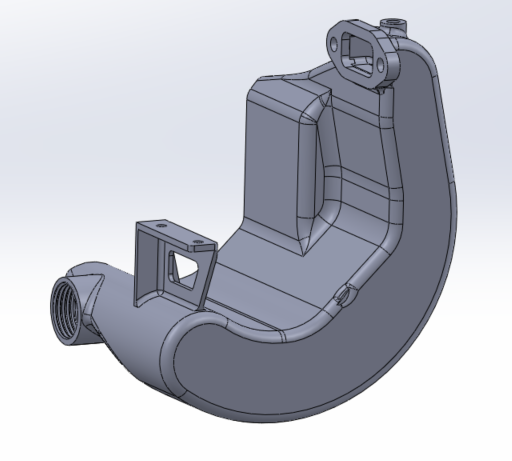

Utilizing 3D printing for manufacturing parts in Unmanned Aerial Vehicles (UAVs) offers groundbreaking advancements, particularly evident in the creation of printed exhaust

systems. Metal printing technology opens doors to unparalleled design freedom, resulting in exhaust designs that boast unmatched performance and efficiency compared to traditional manufacturing methods.

1. Aerodynamic Design:

Our exhaust system is meticulously crafted to optimize the aerodynamics of the powerplant, seamlessly blending with both the engine spinner and fuselage lines. This meticulous design reduces drag significantly, enhancing the speed and agility of your UAV.

2. Weight Reduction:

Additive printing drastically reduces the total weight of the powerplant compared to traditional exhaust systems. By consolidating all components into a single piece, rigidly

attached to the engine without the need for additional accessories, springs, or flanges, weight is minimized without sacrificing performance.

3. Improved Sound Management:

Our exhaust system ensures quiet operation without compromising on performance. By reducing the acoustic footprint of the aircraft, it mitigates noise pollution while enhancing operator comfort during operation.

4. Versatile Adaptation:

Our printed exhaust systems are designed to seamlessly integrate with various engines. As additive manufacturing allows for flexible design modifications, our systems can be adapted to fit any engine available on the market. Experience unparalleled performance and efficiency by upgrading your UAV with our customizable exhaust solutions.

Conclusión:

Revolutionize your UAV’s performance today with our innovative 3D printed exhaust systems. Contact us to learn more about how our solutions can elevate your UAV’s capabilities and transform its performance.